Batch Code Printing Machines

Empower your production line with precision batch coding machines from Macsa.

Batch coding is the process of marking products or packaging with specific information such as expiration dates, serial numbers, and batch numbers for identification.

A batch coding machine automates this process and offers the benefits of accuracy, compliance, and traceability. These machines streamline production, enhance product authenticity, and facilitate regulatory adherence, benefiting businesses across the pharmaceuticals, aerospace, FMCG and automotive industries.

Batch coding solutions

Macsa offers a variety of batch coding machines tailored to distinct industry needs.

Continuous Inkjet (CIJ) Printers

CIJ printers operate by propelling tiny droplets of ink onto the surface to create codes. Ideal for high-speed production lines and providing non-contact, reliable coding on various surfaces. Their versatility in handling different ink types and offering customisable printing fonts and sizes makes them an ideal choice for industries requiring continuous, high-quality coding.

Ideal for printing on all materials, including plastics, metals, glass, paper, and cardboard.

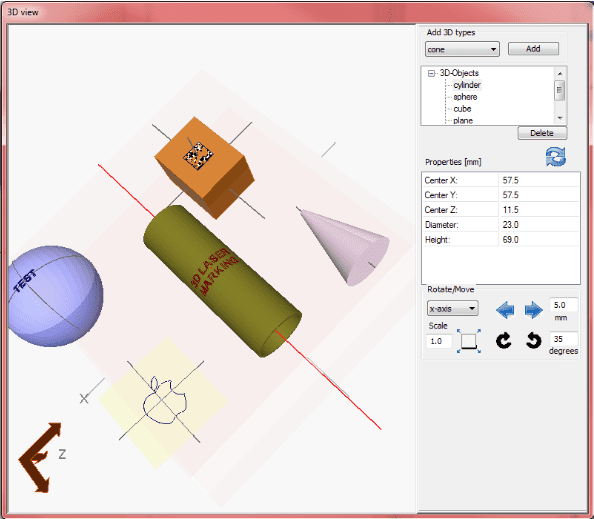

Laser Printers

Renowned for their precision and adaptability, laser printers use laser technology to etch or mark surfaces. Their non-contact nature ensures clean, permanent codes without affecting the integrity of the material. Macsa’s Laser Printers excel in handling intricate designs, variable data, and high-resolution prints, making them indispensable for industries demanding accuracy and durability in coding.

Ideal for printing clear and precise codes on all materials including paper, cardboard, plastics, and certain metals.

Thermal Inkjet Printers

Thermal Inkjet Printers utilise thermal technology to produce high-resolution prints by heating and propelling ink onto surfaces. These printers excel in delivering crisp, clear codes on both porous and non-porous materials. Their adaptability to various inks and ability to produce high-quality codes swiftly make them a preferred choice for applications requiring intricate details and variable data.

Ideal for printing on porous materials like paper and cardboard, but certain models can also handle non-porous materials like plastic and coated metals.

Macsa’s batch coding machines

There are a range of different options to apply batch coding to your products. Deciding on the optimum solution for your organisation depends on your specific requirements, the nature of the production process and the types of products or packaging they need to be applied to.

Here we have summarised our different solutions and the key differences between them.

CIJ printers operate by continuously ejecting tiny droplets of ink through a printhead nozzle.

- As the name suggests, CIJ printers are designed for continuous, high-speed operation making them ideal for rapid production without the need for frequent maintenance

- CIJ printers can handle a wide range of character sizes including larger characters, making them particular beneficial where larger codes or markings are a necessity

- CIJ printers can handle a wide variety of materials including porous and non-porous materials making them ideal for a range of packaging materials

- Made for industrial environments, they are built to handle dust, humidity and temperature variations

- CIJ printers typically use solvent-based inks that dry quickly, again ideal for where production speed is of the essence

TIJ printing is a non-contact ink-based technology that heats ink forcing a droplet out of the printhead nozzle onto the printing surface.

- High resolution printers for sharp and clear images and text – especially useful for smaller characters

- Variable data printing allows for ease of customisation along the production line where each product may have unique information

- They are easy to use and operate in comparison to a CIJ printer, often requiring less operator training

Water-based inks can be advantageous for certain applications which may be required for regulatory purposes or for eco-friendly credentials.

Laser coding machines are a non-contact, low-maintenance form of printing. The laser beam interacts with the material causing it to change colour or texture, creating a permanent mark.

- Marks left by lasers are resistant to abrasion, chemicals and other environmental factors making them ideally suited for applications where long-term readability is key (e.g. automotive, aerospace)

- Laser marks have high resolution and sharp edges providing excellent print quality and the ability to produce intricate designs and small details

They can be used across a range of materials, including delicate substrates.

TIJ printing is a non-contact ink-based technology that heats ink forcing a droplet out of the printhead nozzle onto the printing surface.

- High resolution printers for sharp and clear images and text – especially useful for smaller characters

- Variable data printing allows for ease of customisation along the production line where each product may have unique information

- They are easy to use and operate in comparison to a CIJ printer, often requiring less operator training

Water-based inks can be advantageous for certain applications which may be required for regulatory purposes or for eco-friendly credentials.

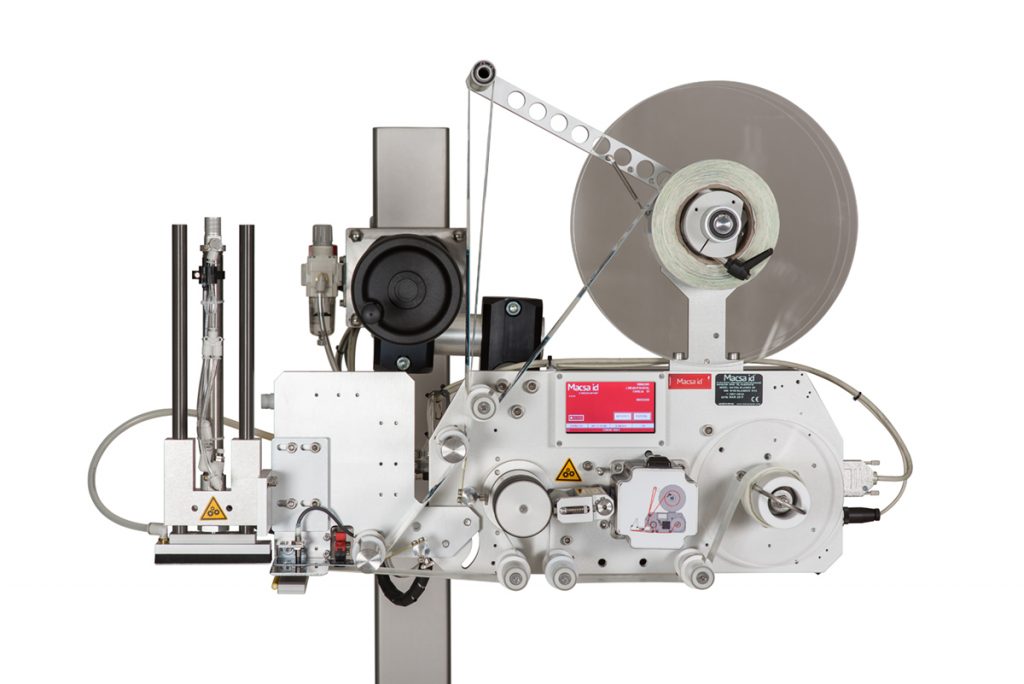

In print and apply technology, codes are printed onto labels which are then automatically applied to the products or packaging.

- A great medium for variable printing where unique information is required on each label in real-time

- Their compact design make them fantastic where space is limited

- Print and apply systems are ideally suited to industries where products may undergo frequent packaging changes and therefore cannot use more permanent forms of marking

- Print and apply systems are ideally suited to industries where products may undergo frequent packaging changes and therefore cannot use more permanent forms of marking

- Label materials can vary from paper and film to synthetic materials

Not sure which solution is right for you?

Why Choose Macsa for Batch Coding Solutions?

With over 100 years’ experience as a world leader in coding, tracing and marking, we have developed batch coding solutions tailored to a wide range of sectors, materials and production environments.

Industry 4.0 Software

Our Integranet 4.0 software provides monitoring, predictive maintenance, remote assistance & support.

Sustainable & Innovative Solutions

Recognised as a world leader in technological innovation for laser technology use in marking and coding and pushing its agenda thanks to its sustainable credentials.

Integration

Seamlessly integrate into your existing production line, software and control systems for fully automatic operations.

Compliance

Fully compliant with CE, RoHSII, ISO9000 and FDA regulations.

Worldwide Presence

With presence in over 80 countries worldwide, Macsa can help you scale whilst remaining fully compliant with local legislation.

Guaranteed product

traceability

Our coding systems enable products to be identified throughout the entire length of the supply chain (‘from farm to fork’!), guaranteeing traceability.

Batch Coding Examples

Explore how our clients use our batch coding machines on a range of different materials to ensure efficiency and precision across their production systems.

Explore Other Coding Solutions

Improve the marking and coding of your company while reducing your environmental impact

Consumable free

Clean, waste free technology

Ecological

No harmful emissions. Good for the work environment and for the planet.

Clean

It will allow you to enjoy a cleaner and safer work space.

Energy efficient

Maximum quality and market speed with minimum energy consumption.