By 3 July 2024 (and to facilitate recycling) it will be mandatory for all plastic bottles to have the cap attached to the container, and the cap is therefore a new surface for product coding and traceability. This is dictated by Directive 2019/904 of June 2019 of the European Parliament on the reduction of the impact of certain plastic products on the environment.

Table of contents

- Introduction

- The new regulation

- An opportunity for emotional impact on consumers

- The Macsa ID response

- Conclusions

1. Introduction

You may have noticed a slight difference when screwing the top off a plastic bottle or opening a carton: the cap is attached to the container. That’s not a production fault – these are the new plastic caps that some brands have already started to implement in order to adapt to the new EU requirements on single-use plastics.

Directive 2019/904 of the European Parliament and of the Council, which is part of the European strategy on single-use plastics, aims to reduce the amount of plastic waste in the environment. It establishes that single-use plastic products with lids and plastic caps “may be placed on the market only if the lids and caps remain attached to the containers during the products’ intended use stage”.

According to this Directive, and specifically Article 6, these product design requirements are to be applied on a mandatory basis as of 3 July 2024. All beverage packaging manufacturers in the EU must, by the deadline, have converted their production systems to comply correctly with the adaptation in terms of packaging design.

2. The new regulation

This application focuses on single-use plastic products such as beverage bottles or composite beverage containers used for beer, wine, water, soft drinks, juices and nectars, instant drinks or milk, but not cups for such drinks, as these form part of a separate category of single-use plastic products for the purposes of this Directive.

The Directive is categorical regarding these single-use plastic packaging and containers, stating that they can only be placed on the market if they meet certain specific requirements in terms of design, more particularly with regard to the cap, to significantly reduce pollution of the environment from plastic lids and caps.

It is also true that this is an obligation that companies may particularly appreciate, because if they have to change their plastic caps or lids anyway, they will do so in such a way as to help considerably reduce the consumption and use of plastic, benefiting both the company and the environment.

This is due to the fact that the bottles will be smaller, once the new regulation brings in the mandatory change, as they have to make sure that the caps can fit onto them. They will be two millimetres shorter and one gram lighter than the previous version. The cap, like the bottles, will be shorter, reducing the weight by 0.4 grams per cap, which means that much less plastic is used to make both the caps and the bottles.

Saving costs with change – Tethered Caps

(Source: https://www.krones.com/en/company/press/magazine/trend/tethered-caps-cost-saving-change-over.php)

3. An opportunity for emotional impact on consumers

In the digital world, consumers are more informed and empowered than ever before. Connected packaging continues to represent a real revolution on supermarket shelves, giving the opportunity to make an impact on the consumer at the point of purchase.

The latest trends in coding and marking of packaging allow not only a connection to software that controls, manages and optimises the production line and traceability, but also QR code marking.

These types of codes are an interactive way for customers to set reminders on their smartphones about the product. QR codes can be used to guide the audience to the brand’s website or social media profiles, enhancing and increasing their online presence. Offering product information, prize draws, promotions, videos or loyalty programmes are just some of the many interaction options available.

This serves to achieve better communication with the public, as they can interact with the company in a quick and easy way. The marking of the attached plastic caps will help companies build a portfolio of innovation and competitive differentiation, which will in turn increase customer engagement, brand awareness and brand loyalty.

3.1. The solution to encourage recycling

Many opinions on the new regulation have been less than positive, with some consumers commenting that they find the new closure system inconvenient. Others have meanwhile pointed out that, as the regulation will be mandatory and will be present on all packaging, it will mark the end of charity initiatives based on plastic caps. These involve collecting the caps to raise funds for various causes, such as those affecting patients with rare diseases.

The fact is that brands have already been using the new carton cap for months without the slightest fuss. So once users get used to this new system, there will be no complications whatsoever. It is easy to adapt to change. On the other hand, we must also remember the basis of this great change: recycling and sustainability. We will see to what extent such a seemingly simple thing will reduce pollution on the beaches and in the rest of the world, and so help to preserve the planet. Because small changes, however insignificant they may seem, also make a difference.

4. The Macsa ID response

Within Macsa id’s wide range of marking solutions, laser technology is the optimal choice for marking caps and closures with minimal thermal impact, which is crucial to avoid damage or deformation on heat-sensitive plastics. Laser offers the legible, high contrast and long lasting marking that is essential in this sector.

In addition, customisability and traceability are essential in the bottling industry, especially when it comes to marking expiry dates, batch numbers or barcodes. Macsa id solutions allow variable information to be encoded quickly and accurately, meeting regulatory requirements, improving production efficiency and ensuring product traceability.

Laser marking on polypropylene caps

Conclusions

The future of packaging in 2024 will be marked by sustainability, technology and a focus on the consumer experience. It is the responsibility of companies to adapt and to embrace these trends, so as to meet consumer demands and thrive in an ever-changing world.

Packaging will not only remain an essential part of the industry, but will also continue to become a key tool for communicating company values and enhancing the consumer experience.

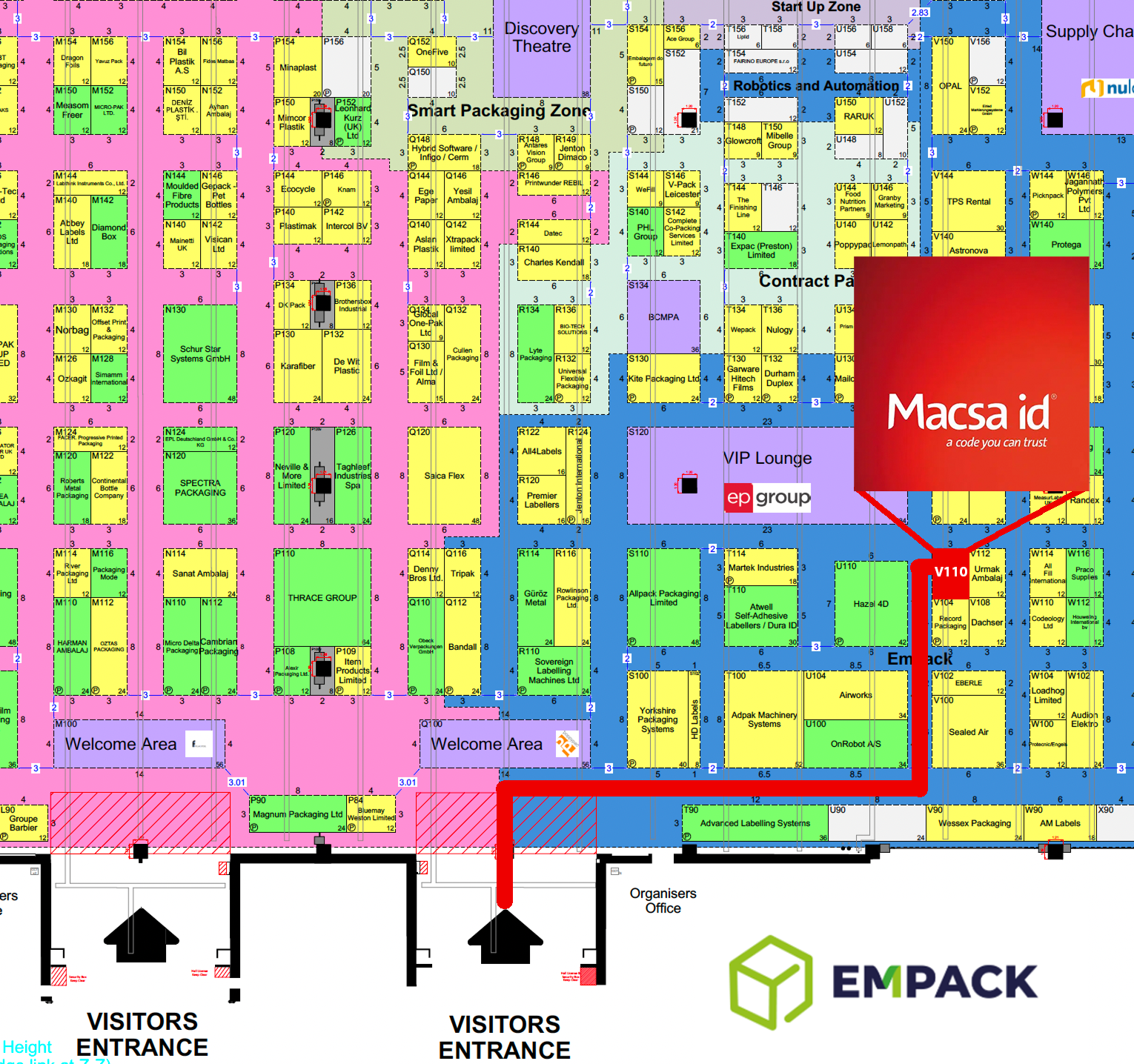

Do you want advice on Macsa ID solutions to meet the new requirements?

Desde Macsa id estaremos encantados de encontrar la solución de marcaje, codificación y trazabilidad que mejor se adapta a tus necesidades