New materials for the food industry: a problem or an opportunity?

The packaging industry is developing new and interesting solutions for food manufacturers.

These solutions seek to increase product shelf life and at the same time guarantee freshness, quality and safety. They will feature new materials and more sustainable, reusable designs that reduce food waste and waste generation.

It is a challenge that also responds to modern-day consumer demand, given increased awareness of the need to protect the environment, meaning consumers are looking for products from brands committed to sustainability.

Table of contents

- Maximum innovation in materials

- New trends in food packaging

- Materials traditionally used in food

- Macsa ID’s challenges in new food packaging

Maximum innovation in materials for the food industry.

The materials used in the manufacture of packaging for the food industry nowadays have to strike a balance between the demands of food safety and those of sustainability criteria.

From this perspective, various alternative packaging materials are being launched on the market to meet these new requirements of the food industry. This is the case, for example, of active packaging, edible films and bioplastics.

Would you like to have a personalized consultation?

According to the definition from the Ainia technology center, “active packaging is a packaging system that plays a specific role, in addition to that of constituting a physical barrier between the product they contain and the outside, and plays an active role in maintaining or even improving the quality of the packaged food. A key characteristic is the capacity to extend the shelf life of packaged food. In addition, they maintain the sensory and nutritional properties of the food and contribute to the ease of use for the consumer and convenience”.

Edible film is made from a very thin layer of an edible polymer that allows fruits, vegetables and other foods to be coated, delaying their decomposition and improving both their color and their aesthetic appearance. Some of the substances most commonly used as edible films are gelatin, chitosan, wheat gluten or corn protein.

Finally, bioplastics, also known as vegetable plastics, are 100% biodegradable natural polymers, which are produced in nature during the process of biosynthesis. Their development is the result of the need to find an alternative material to plastic, but with similar characteristics and from non-polluting sources.

One example is the polyesters known as polyhydroxyalkanoates (PHA), produced by fermentation of a vegetable raw material with certain strains of bacteria.

Among others, the advantages of bioplastics are the following:

- They are non-toxic to humans

- They do not contain additives harmful to health

- They do not modify the taste and aroma of the food they contain

- They do not pollute natural environments

- They help in the preservation of the environment

- They are easy to dispose of and degrade rapidly

- They contribute to lengthening life cycles

- They are produced from renewable raw materials

- They consume less energy in their manufacture

- They decrease CO2 emissions and reduce carbon footprints

New trends in food packaging

In addition to the sustainable demands of modern consumers, legislative changes must also be taken into account in order to understand the evolution of trends in the food sector. Given the nature of food, these standards and regulations are much stricter than those existing in other industrial sectors, due to their requirements to ensure consumer health and safety.

Numerous international organizations have been adopting rules and regulations in relation to the new characteristics of food packaging. These range from the FDA in the US to supra-state institutions such as the European Union, MERCOSUR (South America), ASEAN (Asia), COMESA (Africa) or qualified entities such as the International Organization for Standardization (ISO), the Global Environmental Management Initiative (GEMI) and the International Commission on Microbiological Specifications for Foods (ICMSF).

In this international context, the use of packaging materials that favor recyclability is one of the first trends to be considered, since packaging made of 100% mono-materials is being launched on the market, relying on different technology such as lamination or the use of bio-orientation in its transformation process.

Other predicted trends in food packaging are the reduction in material weight, the use of paper and cardboard as alternative materials, the introduction of chemical recycling and the use of compostable materials.

In the case of reducing the weight of the material used, there is both an economic and an environmental component, and for this reason the so-called “bag in box” or boxes with a plastic bag that allows the product to be dosed are being introduced. According to new R&D, a reduction in the weight of packaging waste produced is expected; of 13% in 2025 and 15% in 2030 compared to that generated in 2010. Additionally, all packaging should be 100% recyclable by 2030 and, if possible, also reusable.

In food packaging, paper and cardboard have always been present, but they are becoming another alternative to the use of plastic laminates with solutions that incorporate aqueous dispersions, which do not alter their recyclability.

Would you like to know more?

With regards to the introduction of chemical recycling in the food sector, Ainia points out the existence of authorized processes for recycling PET and its incorporation as a material suitable for contact with food.

Moreover, compostable material is also gradually making its way onto supermarket shelves although at a slower pace than expected. According to researchers at Ainia, the main applications are tableware (cups, cutlery, plates, etc.) along with coffee capsules, bags for packaging fruit and vegetables, as well as organic waste bags.

Other trends point to an increased use of materials based on organic matter for packaging, such as bio-based materials. In the case of food, one biodegradable polymer with high performance and high density is polylactic acid (PLA).

Another noteworthy mention is the organic polymer lignin, which increases the barrier properties of finished products in the production of packaging. It is beginning to be used to produce bags, packaging films and coatings.

Other bio-based materials that are beginning to gain prominence in the sector are starch, limestone (sedimentary rock) and biopolyethylene terephthalate (Bio-PET).

Materials traditionally used in food

Biopolyethylene terephthalate (Bio-PET) emits less carbon and is more suitable for recycling than polyethylene terephthalate (PET). This lightweight, semi-rigid or fully rigid plastic has been commonly used in liquid food and beverage packaging because of its impact resistance.

Along with PET, other plastics also traditionally used in food which may also sometimes be recyclable, are:

- High-density polyethylene (HDPE), used especially in milk and juice containers.

- Polyvinyl chloride (PVC), used for shrink-wrapping and packaging of various products.

- Low-density polyethylene (LDPE), used in bread bags, fruit and vegetables and ring binders for beverage packs.

- Polypropylene (PP), used for containers.

- Polystyrene (PS), used to make trays, containers and lids for different types of food.

In addition to this range of synthetic plastics, other raw materials also used in the manufacture of food and beverage packaging are:

- Paper and cardboard, cellulose-based materials that are permeable to gases and water vapor.

- Glass, especially for the production of bottles and jars, which can be pasteurized at high temperatures. They can be recycled multiple times, but at a high energy cost.

- Metals such as steel and aluminum, used for the manufacture of cans. They can be recycled, but have a high energy cost.

All these materials have traditionally been used in the food industry for the manufacture of the most common food packaging. These are usually trays, bags, bottles, cans, boxes and peelable packaging.

Macsa ID’s challenges in new food packaging

Building customer loyalty with functional and distinguishing packaging designs that provide value to the customer will no longer be enough. It will be necessary to contextualize the role of packaging in sustainability and food safety issues, under the premise of building products with new solutions and materials that improve the health and well-being of people, as well as helping to build a better world for everyone.

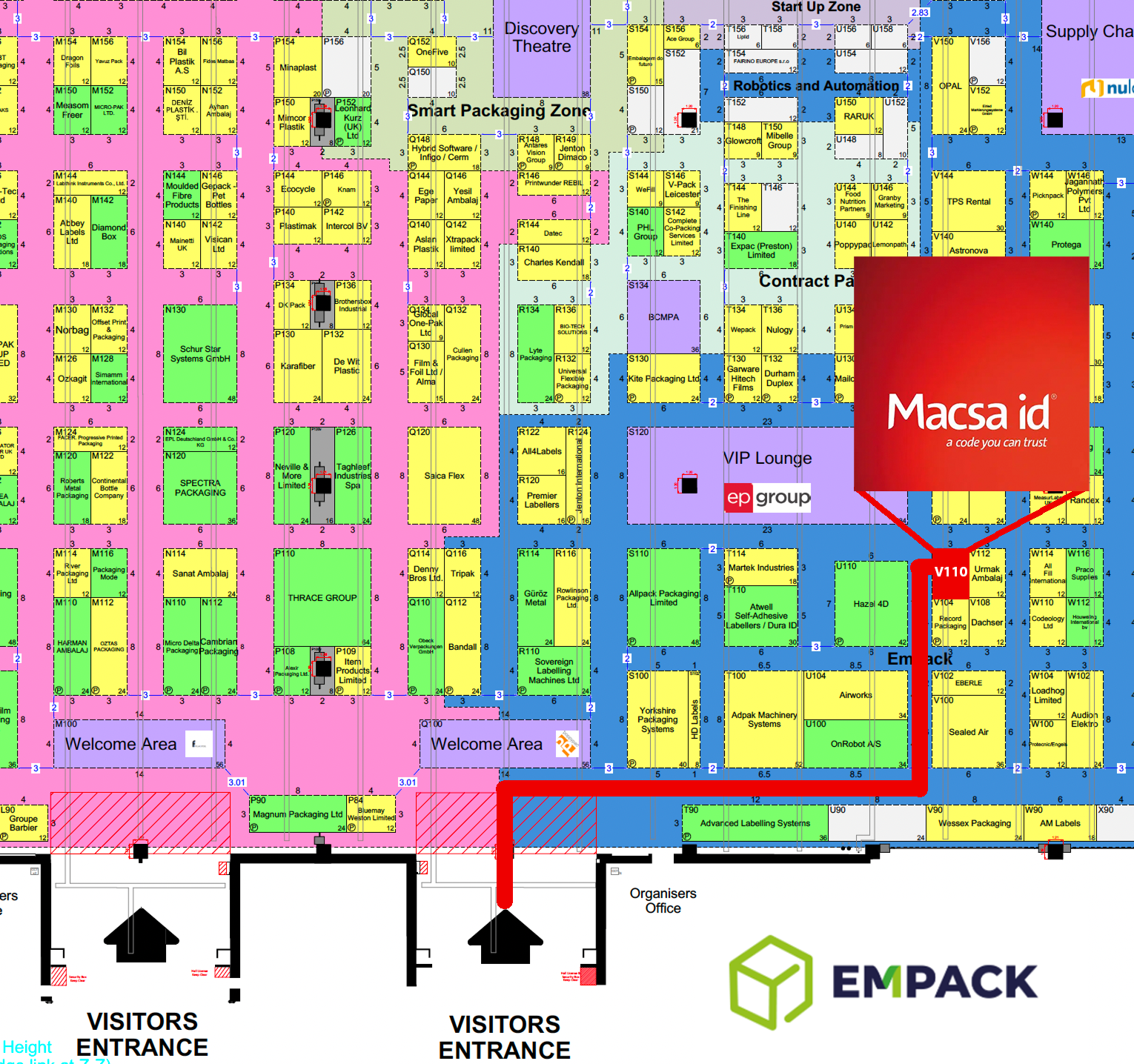

In this sense, all these new trends in the food packaging sector are a great challenge for Macsa ID and an opportunity to develop the most innovative solutions that rise to the challenges of today’s markets and consumers.

As a leading company in coding, marking and traceability solutions, the company dedicates significant R&D resources to adapting our technology to the requirements of future food packaging, where product information is essential.

Currently, Macsa ID offers a wide range of technology for marking and coding on the main materials and substrates used in the food packaging industry, but also in other productive (medicine, pharmaceuticals, cosmetics…) and industrial (automotive, aeronautics, defense, building materials…) sectors.

These materials and substrates range from paper, cardboard, film, aluminum, glass, organic, PET, engineering plastics, PVC, wood, steel, clay, metals all the way to textiles. In line with the three Rs policy (reduce, reuse and recycle), many of these materials are particularly easy to recycle.

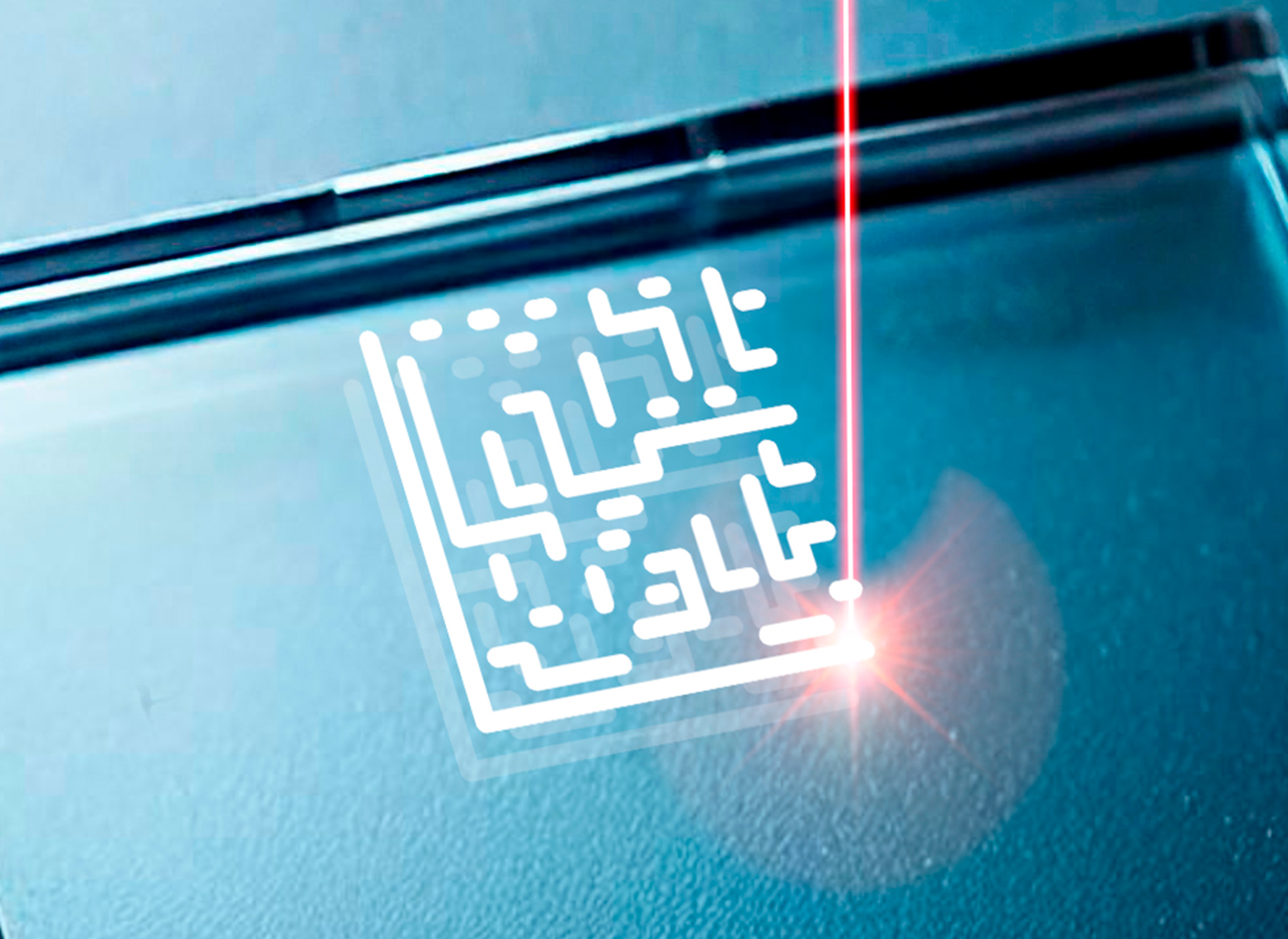

This wide variety of materials can be coded and marked, thanks to the technology of our different lasers and management software, in order to ensure logistical management of products until they are sold.

Regarding new sustainable materials such as bio-labeling or bio-wrapping that will allow plastics to be replaced with 100% recyclable materials, Macsa ID is working alongside different strategic partners to provide solutions to this new demand from large distribution chains.

Along these lines, laser technology meets all the conditions to become the perfect solution in terms of sustainability and safety that are being implemented in the food packaging sector. This is because it does not generate harmful emissions or waste that can affect people and the planet, does not use consumables and operates with efficient and optimal energy use.

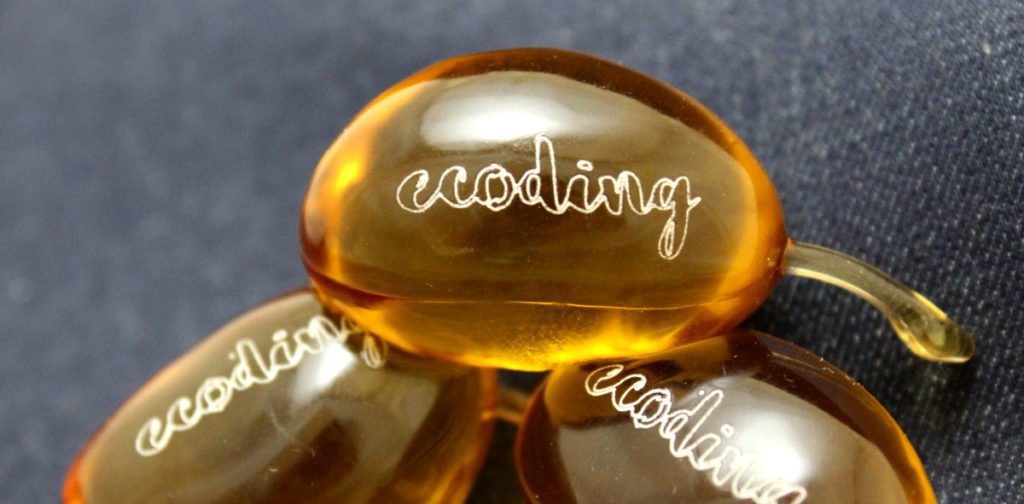

Another big advantage of laser technology is the possibility of marking onto the food itself, which is highly valued in the food industry.

Laser marking directly onto products is becoming more and more common in the food industry. In fact, one of the main areas of focus for the packaging industry in terms of sustainability is the elimination of unnecessary packaging and labeling that does not allow recycling. Marking food directly with laser technology saves costs in packaging, avoids the generation of consumable waste and leaves no footprint on the environment as it is a clean technology.

Laser coding on food also allows it to be sold in bulk or individually, without losing traceability. In addition, they can be identified with the brand if the corporate logo or image is chosen for the marking.

At Macsa ID we will be happy to find the marking, coding and traceability solution that best suits your needs.