Fibre Laser Marking Machines

Industrial fibre laser marking solutions that offer exceptional speed and precision to meet the demands of a range of industries.

Fibre lasers use fibre optics to produce a concentrated and powerful beam, ideal for marking and engraving a diverse range of materials.

Their exceptional capability to deliver high-quality, fine, and permanent marks makes them indispensable across industries including aerospace and automotive industries. On this page, find the best fibre laser marking solution for your business.

Why choose fibre laser marking?

Stability

Fibre lasers are extremely stable, creating a fine and focused beam. This achieves exceptionally precise, clear markings (with no scattering/distortion) and excellent edge definition.

Reduced operating costs

Their energy consumption is low, which leads to much lower running costs.

Environmentally friendly

They do not use consumable materials such as dyes, inks or stylus tips.

High contrast

By adjusting the power and pulse duration, higher contrast can be achieved by either localising the oxidation, melting or creating chemical changes in the materials.

Increased operational efficiency

Fibre lasers use a solid-state laser source leading to higher marking speeds and increased operational efficiency.

Ease of integration and automation

Fibre lasers are extremely easy to integrate into production lines and setup automation rules within existing workflows.

Excellent precision on a range of metals, plastics and ceramics

This includes copper, titanium, silver, iron and a range of plastics making it ideal for electronics, tool marking, serial etching, jewellery marking/stamping, QR code and barcode marking (to name a few).

Flexibility

Fibre lasers are extremely easy to programme and can produce crisp markings of images and codes in both micro and macro formats.

Permanence

The marks left by fibre lasers are extremely permanent even when exposed to different temperatures, chemicals or gases making them ideal for traceability.

No contamination

With no-contact required, this means there is no risk of contamination between parts.

Our range of fibre laser marking machines

Fibre laser coding, as well as CO2 laser and UV laser, are attractive alternatives to inkjet where carbon emissions are concerned because they consume less energy and because there are no solvent emissions. Find your perfect laser coding solution from our range below:

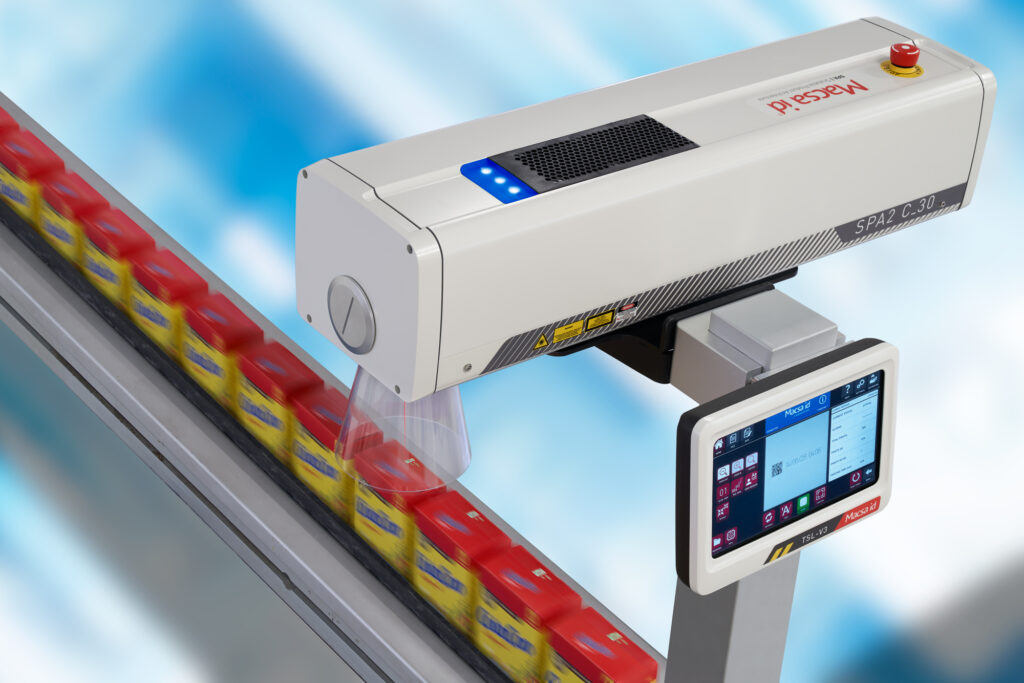

SPA2 F PULSED

ALUMINIUM

PLASTICS

ORGANIC

Macsa ID’s SPA2 F range codes and marks product information without damaging the substrate at very high speeds while maintaining excellent definition.

SPA2 F FILM

FILM

Fibre film lasers are widely used in packaged goods applications, including trays, pouches and wraps, where it is important not to perforate the packaging.

Trusted by businesses across the globe

Why choose Macsa fibre laser marking machines?

Fibre lasers, as well as UV lasers and CO2 laser coders, are attractive alternatives to inkjet where carbon emissions are concerned because they consume less energy and because there are no solvent emissions. Discover the precision and reliability of our fibre laser series tailored to meet diverse industry demands:

Industry 4.0 software

Our Integranet 4.0 software provides monitoring, predictive maintenance, remote assistance & support.

Sustainable & innovative solutions

Recognised as a world leader in technological innovation for laser technology use in marking and coding and pushing its agenda thanks to its sustainable credentials.

Integration

Seamlessly integrate into your existing production line, software and control systems for fully automatic operations.

Compliance

Fully compliant with CE, RoHSII, ISO9000 and FDA regulations.

Worldwide presence

With presence in over 80 countries worldwide, Macsa can help you scale whilst remaining fully compliant with local legislation.

Guaranteed product

traceability

Our coding systems enable products to be identified throughout the entire length of the supply chain (‘from farm to fork’!), guaranteeing traceability.

Fibre laser marking examples

Explore how our clients use our fibre laser marking machines on a range of different materials.

Looking for other laser solutions?

Improve the marking and coding of your company while reducing your environmental impact

Consumable free

Clean, waste free technology

Ecological

No harmful emissions. Good for the work environment and for the planet.

Clean

It will allow you to enjoy a cleaner and safer work space.

Energy efficient

Maximum quality and market speed with minimum energy consumption.