We’re refreshing our website so you might notice some changes as they go live, but everything you need is still here.

We’re refreshing our website so you might notice some changes as they go live, but everything you need is still here.

The EU’s new Packaging and Packaging Waste Regulation (PPWR) marks a significant overhaul in European packaging standards with a focus on sustainability: minimising packaging, improving recyclability and increasing the use of recycled material. While the United Kingdom is no longer an EU member, the PPWR has direct and wide-reaching consequences for UK-based manufacturers, exporters, and importers integrated with European markets.

The PPWR is a sweeping regulation intended to:

Export Compliance with EU Standards

UK businesses exporting goods to the EU must ensure all packaging—whether primary, secondary, or tertiary—is compliant with PPWR. This covers material composition, recyclability, use of recycled content, and labelling requirements. Non-compliance could lead to delayed shipments, rejected goods, or penalties.

Changing Import Packaging

As EU suppliers transition to PPWR-compliant packaging, UK importers will encounter changes in:

Packaging formats and materials

Labelling

Handling, storage, and disposal processes

Automation and logistics systems may require updates to accommodate these changes.

Stronger Supply Chain Integration

The regulation demands close coordination throughout supply chains. Failures in compliance at any stage—including component suppliers or logistics partners—may disrupt the entire chain. Contracts, audits, and supplier relationships will increasingly factor in packaging compliance criteria.

Rising Consumer and Retail Expectations

UK businesses lagging behind PPWR principles could lose retail listings or customer trust, even if not directly exported to the EU.

Area | PPWR Requirement | UK Business Impact |

Recyclability | All packaging must be effectively recyclable by 2030 | Rethink material choices and avoid complex composites |

Recycled Content | Mandated: eg. 30% for some plastics, rising over time | Secure certified recycled materials and ensure traceability |

Waste Reduction | Targets for reducing all packaging and plastic packaging | Audit packaging processes, eliminate over-packaging |

Reuse/Refill | % of packaging must be reusable in key sectors | Invest in reusable packaging, reverse logistics systems |

Labelling | Harmonised, clear, detailed instructions | Adapt print processes, manage multi-market label compliance |

Bans/Restrictions | Certain single-use and non recyclable formats prohibited | Redesign products/packages as needed |

At Macsa id UK, our extensive range of coding, marking, and traceability solutions is designed to help your business seamlessly adapt to evolving regulatory requirements, such as the PPWR. Beyond basic compliance, PPWR demands operational transformation of coding systems. Legacy equipment may lack the data integration capabilities needed for real-time batch tracking and recycled content verification that the regulation requires.

Here’s how our offering supports UK and EU compliance:

Advanced hardware: High-precision laser, inkjet, and labelling systems compatible with all packaging materials, from product to pallet.

Integrated software: Smart solutions for adding essential product identification, batch codes, best-before dates, and recycling instructions—essential for compliance with harmonised EU labelling.

End-to-end traceability: Robust supply chain traceability, securing the integrity and transparency demanded by both regulators and clients.

Optimised efficiency & sustainability: High-speed equipment for the most demanding applications reduces operational costs and supports reduced packaging footprints.

Consultative support: Expert guidance to tailor coding and marking technologies for sustainable packaging and dynamic regulatory landscapes.

Now: System Preparation

September 2025 - July 2026: Final Preparation

August 2026 onwards: Full Implementation

Businesses that proactively align with PPWR requirements will be positioned to:

At Macsa id UK, we are large enough to innovate but small enough to care. Let us help your business navigate the challenges and unlock the opportunities of the new PPWR.

[contact-form-7 id="16985" title="Contact form - Inboud Colours - Post SPARK Catalogo English"]

[contact-form-7 id="16985" title="Contact form - Inboud Colours - Post SPARK Catalogo English"]

I WOULD LIKE A PERSONALISED MEETING

I WOULD LIKE A PERSONALISED MEETING

Empack Oporto 2023 is just around the corner and we are looking forward to sharing our latest solutions in coding and traceability 4.0 with you at the show.

Empack Oporto 2023 is just around the corner and we are looking forward to sharing our latest solutions in coding and traceability 4.0 with you at the show. The term 'Green Supply Chain management' (GSCM) refers to the concept of integrating sustainable environmental processes into the traditional supply chain. This can include processes such as product design, material sourcing and selection, manufacturing and production, operation and end-of-life management.

In recent years, research in the area of green manufacturing has extended into green supply chain management. Achieving highly responsive, sustainable supply chain performance is the key to securing a competitive advantage, as well consumer loyalty and long-term business success.

Organizations worldwide are acutely aware of this, but implementing green supply chain management is no simple task. Traditionally, supply chain management has been about cost and quality. Growing concern for the environment has forced a rethink.

In this article you will get an overview of the challenges it involves and Macsa id’s comprehensive solution to get along in this new scene.

![]()

The Cycle of Green Supply Chain

The Macsa id SPA2 Can Coding

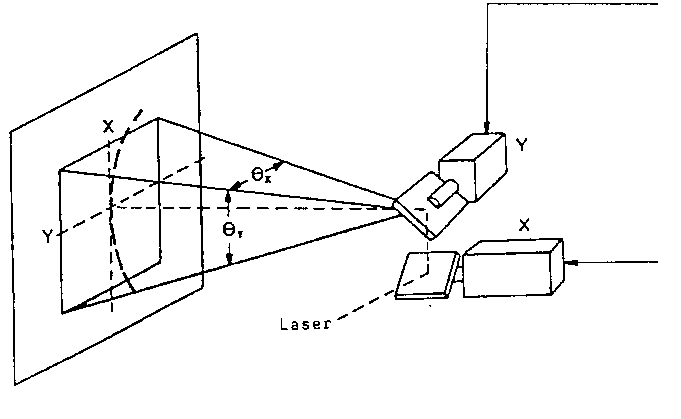

It works in the same way as galvanometers that control the motion of X-Y scanners. A galvanometer is based on and works like an electric motor.

Displacement systems can have 2 galvanometers, one on each side for higher speed performance.

These are motors that base their operation on the same physical principle as traditional rotary motors, but instead of having a rotary motion they have a linear motion due to the arrangement of their components.

These motors are considered linear but follow the piezoelectric principle in operation. This principle uses the deformation experienced in some materials when an electric current is applied to them. This deformation is converted into an ultrasonic vibration that moves the motor forwards/backwards.

This motor is based on a copper coil energized by an electric current and placed inside a magnetic field generated by permanent magnets. The force generated by the coil is proportional to the magnetic field and to the direction and magnitude of the electric field. As there are no components in contact, there is no wear or friction and it is suitable for high speed applications.

All these linear lens displacement systems will normally be controlled by drivers connected to the central CPU of the laser system.In addition to the above, depending on the application of the 3D laser marking system, an F-Theta lens may or may not be included. The function of these lenses is to ensure the same focal length over the entire marking area. Focus-tunable lens The 3D technology we are going to explain below is based on physical properties to control the Z-axis.The electrically focus-tunable lens is a flexible lens that can change its shape. This lens consists of a polymer membrane surrounded on one side by a type of liquid and on the other side by air. Finally, it is encapsulated by protective glass.The lens works as follows: If the pressure difference between liquid and air is altered by means of an electromagnetic actuator, the radius of curvature of the membrane can change.In the marking head, these tunable lenses are positioned between the laser tube aperture and the X-Y galvanometer scanners. Their function in the optical path is the same as that of the displaceable lens, i.e. to control and change the position of the Zaxis.As in the previous case, depending on the application, an F-Theta lens may or may not be added at the end of the optical path.If it is added, its function is to ensure the smoothing of the marking area and the function of the tunable lens is to change the divergence of the laser beam to achieve a focus shift in the Z-axis.If the F-Theta lens is not added, the two functions discussed above must be performed by the tunable lens.The tunable lens is controlled by a driver connected to the laser system's CPU and allows real-time control in conjunction with the X-Y scanners to achieve perfect 3D marking.

If you are looking for the best laser solution, do not hesitate to contact us:

Take away detailed information for our SPA range. If you provide your email address, we’ll send contact details of your personal product advisor for any future questions.

Take away detailed information about our coding, tracing and marking solutions.