We’re refreshing our website so you might notice some changes as they go live, but everything you need is still here.

We’re refreshing our website so you might notice some changes as they go live, but everything you need is still here.

The EU’s new Packaging and Packaging Waste Regulation (PPWR) marks a significant overhaul in European packaging standards with a focus on sustainability: minimising packaging, improving recyclability and increasing the use of recycled material. While the United Kingdom is no longer an EU member, the PPWR has direct and wide-reaching consequences for UK-based manufacturers, exporters, and importers integrated with European markets.

The PPWR is a sweeping regulation intended to:

Export Compliance with EU Standards

UK businesses exporting goods to the EU must ensure all packaging—whether primary, secondary, or tertiary—is compliant with PPWR. This covers material composition, recyclability, use of recycled content, and labelling requirements. Non-compliance could lead to delayed shipments, rejected goods, or penalties.

Changing Import Packaging

As EU suppliers transition to PPWR-compliant packaging, UK importers will encounter changes in:

Packaging formats and materials

Labelling

Handling, storage, and disposal processes

Automation and logistics systems may require updates to accommodate these changes.

Stronger Supply Chain Integration

The regulation demands close coordination throughout supply chains. Failures in compliance at any stage—including component suppliers or logistics partners—may disrupt the entire chain. Contracts, audits, and supplier relationships will increasingly factor in packaging compliance criteria.

Rising Consumer and Retail Expectations

UK businesses lagging behind PPWR principles could lose retail listings or customer trust, even if not directly exported to the EU.

Area | PPWR Requirement | UK Business Impact |

Recyclability | All packaging must be effectively recyclable by 2030 | Rethink material choices and avoid complex composites |

Recycled Content | Mandated: eg. 30% for some plastics, rising over time | Secure certified recycled materials and ensure traceability |

Waste Reduction | Targets for reducing all packaging and plastic packaging | Audit packaging processes, eliminate over-packaging |

Reuse/Refill | % of packaging must be reusable in key sectors | Invest in reusable packaging, reverse logistics systems |

Labelling | Harmonised, clear, detailed instructions | Adapt print processes, manage multi-market label compliance |

Bans/Restrictions | Certain single-use and non recyclable formats prohibited | Redesign products/packages as needed |

At Macsa id UK, our extensive range of coding, marking, and traceability solutions is designed to help your business seamlessly adapt to evolving regulatory requirements, such as the PPWR. Beyond basic compliance, PPWR demands operational transformation of coding systems. Legacy equipment may lack the data integration capabilities needed for real-time batch tracking and recycled content verification that the regulation requires.

Here’s how our offering supports UK and EU compliance:

Advanced hardware: High-precision laser, inkjet, and labelling systems compatible with all packaging materials, from product to pallet.

Integrated software: Smart solutions for adding essential product identification, batch codes, best-before dates, and recycling instructions—essential for compliance with harmonised EU labelling.

End-to-end traceability: Robust supply chain traceability, securing the integrity and transparency demanded by both regulators and clients.

Optimised efficiency & sustainability: High-speed equipment for the most demanding applications reduces operational costs and supports reduced packaging footprints.

Consultative support: Expert guidance to tailor coding and marking technologies for sustainable packaging and dynamic regulatory landscapes.

Now: System Preparation

September 2025 - July 2026: Final Preparation

August 2026 onwards: Full Implementation

Businesses that proactively align with PPWR requirements will be positioned to:

At Macsa id UK, we are large enough to innovate but small enough to care. Let us help your business navigate the challenges and unlock the opportunities of the new PPWR.

In today's examples, Macsa id has showcased its prowess in various coding technologies, reaffirming its commitment to excellence in marking:

In today's examples, Macsa id has showcased its prowess in various coding technologies, reaffirming its commitment to excellence in marking:  Macsa's applications encompass comprehensive labels, featuring text, barcodes, logos, and QR codes, providing an overall solution for product identification without altering the aesthetic.In conclusion, the adoption of laser technology for direct product marking brings significant advantages, including improved logistics efficiency, enhanced traceability, cost reduction, and minimized waste. This innovation aligns with industry demands for more sustainable and efficient solutions in supply chain management.s of the transparent plastic.

Macsa's applications encompass comprehensive labels, featuring text, barcodes, logos, and QR codes, providing an overall solution for product identification without altering the aesthetic.In conclusion, the adoption of laser technology for direct product marking brings significant advantages, including improved logistics efficiency, enhanced traceability, cost reduction, and minimized waste. This innovation aligns with industry demands for more sustainable and efficient solutions in supply chain management.s of the transparent plastic.Do you want to know more about the advantages of laser marking on cardboard and plastic?

Laser marking on cardboard offers significant advantages, such as precise coding on high-peed production lines, high accuracy in the reproduction of details, durability of the marking, and the ability to work with various types of cardboard, including coated or specially finished ones. Additionally, laser technology is environmentally friendly as it requires no consumables and generates zero waste, contributing to efficient and eco-conscious marking. The non-contact marking process also prevents the wear and deterioration of the packaged product.

Laser marking on cardboard offers significant advantages, such as precise coding on high-peed production lines, high accuracy in the reproduction of details, durability of the marking, and the ability to work with various types of cardboard, including coated or specially finished ones. Additionally, laser technology is environmentally friendly as it requires no consumables and generates zero waste, contributing to efficient and eco-conscious marking. The non-contact marking process also prevents the wear and deterioration of the packaged product.

Do you want to know more advantages of laser marking on cardboard pots? Tell us your cardboard coding needs

In the pharmaceutical field, traceability and coding have become fundamental pillars to guarantee the quality and safety of products. The regulations regarding coding in the pharmaceutical sector are very strict, often undergoing frequent changes to align with market needs and ensure consumer safety.

Amidst this dynamic environment, effective traceability, which entails monitoring the supply chain from manufacturing to distribution, is enhanced by the accurate coding of each unit. Laser technology has transformed this process, providing an efficient and accurate solution that can adjust to the dynamic nature and requirements of the pharmaceutical sector.

In today's application news, fibre laser technology has been used to mark blister packs on printed aluminium, delivering a comprehensive and effective solution. This innovative approach ensures simultaneous marking of text and QR codes with unparalleled accuracy. Macsa's fibre laser guarantees flawless readability, ensuring the legibility of critical information on each product unit and is ideal for applications for metals and reflective materials.

This solution not only increases efficiency on the production line, but also improves traceability by providing coded data that is easily traceable at every stage of the process, meeting the most demanding standards of the pharmaceutical industry.

Do you want to know more about the advantages of fibre laser marking on printed aluminium blister?

Noteworthy for its exceptional marking quality, UV technology ensures unparalleled accuracy, ensuring sustained legibility over time for a diverse range of markings, including datamatrix, QR codes, alphanumeric, and others.

Noteworthy for its exceptional marking quality, UV technology ensures unparalleled accuracy, ensuring sustained legibility over time for a diverse range of markings, including datamatrix, QR codes, alphanumeric, and others.Do you want to know more about the advantages of PVC laser marking?

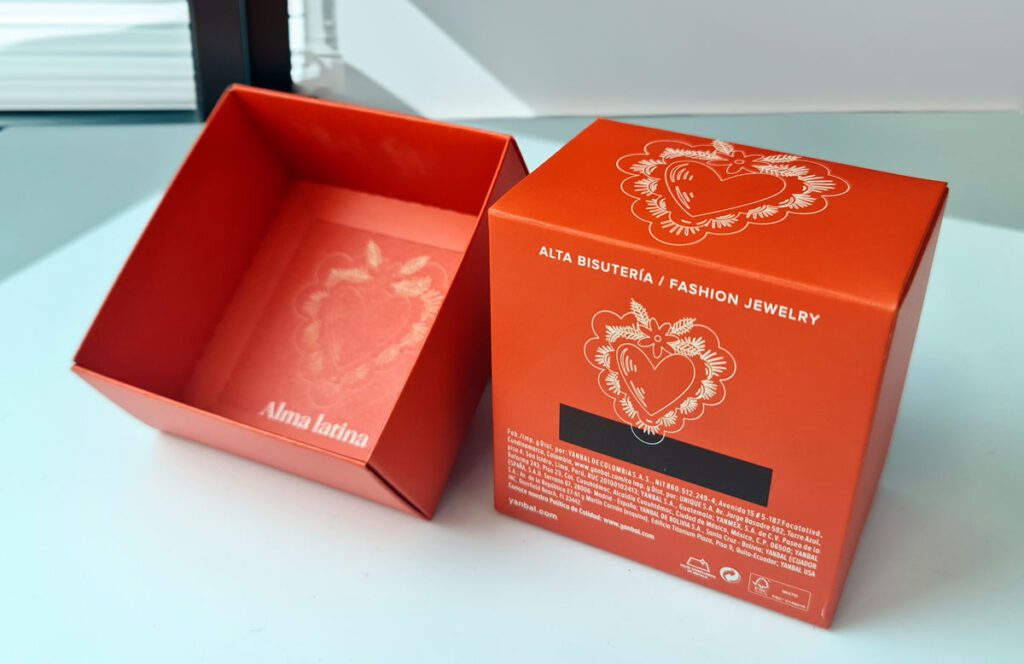

In the world of jewellery, packaging serves as more than just a functional enclosure; it is an essential aspect of the customer's journey, conveying the inherent value of the jewellery and contributing to their overall experience. The careful presentation of a jewel through packaging not only highlights its beauty, but also reflects the brand and its commitment to quality.

Laser technology emerges as an innovative solution capable of fulfilling both aesthetic and functional demands in packaging design. From an aesthetic perspective, lasers allow for precise and intricate engraving on various materials, imparting a unique and sophisticated touch to the packaging of items like jewellery or premium perfumes.

At the same time, laser technology proves to be an effective solution to guarantee the authenticity and traceability of products through the application of unique codes.

In today's Application News a cardboard jewellery box coated with paint has been marked with a CO2 laser. These lasers emit a beam of infrared light that is absorbed by the cardboard. When the laser energy hits the surface of the material, it causes localised heating. The ablation process removes the paint, leaving the cardboard's colour on the surface and creating a distinctive, contrasting mark.

This results in a permanent mark on the carton featuring specific details, making this technology ideal for simple applications such as coding, or more complex markings such as logos, images or decorative elements commonly found in perfumery or jewellery packaging, where precision and aesthetic quality are paramount. In addition, the speed and versatility of CO2 laser technology makes it an efficient choice for carton marking in industrial and production environments.

Do you want more information about laser marking on cardboard jewellery boxes?

Leave us your details and we will contact you shortly to find the best solution.

Take away detailed information for our SPA range. If you provide your email address, we’ll send contact details of your personal product advisor for any future questions.

Take away detailed information about our coding, tracing and marking solutions.